97/23/EC 압력 장비 (PED)

1) 압력용기 지침 PED ( 97/23/EC) 적합성 절차

(1) 압력용기 지침( 97/23/EC)의 구성

서 론 : 해당되는 지침, 전반적인 해설 및 유의사항

본 문 : 적용하기 위한 조문, 가맹국의 법적의무 및 권한

Annex I : 필수 안전 요구사항

Annex II : 적합성 평가 테이블

Annex III : 적합성 평가 절차

Annex IV : 승인기관의 요구조건

Annex V : 사용자 검사관의 요구조건

European Commission에서 제공하는 CE Marking 인증관련 모든 자료가 안내되어있습니다.

(2) 대상기기

대상기기는 최대 허용 압력 0.5 bar 이상을 사용하는 Shell and Water Tube boiler, Heat Exchangers, Plant Vessels, Pressured Storage Containers, Industrial Pipework로써 화학, 정유, 생화학, 식음공정과 에너지 산업 기기류 뿐만 아니라 General Engineering Process에 사용되는 공기가압장비와 가스실린더(Cylinder for breathing air 포함)류 입니다.

다만, 이동용 압력용기 지침 (Transportable Pressure Equipment Directive)과 단순압력용기 지침( Simple Pressure Vessels Directive)에 적용되는 품목은 제외되며 또한 상대적으로 가압이 낮은 제품은 기계지침(기계 지침)에 따릅니다.

일반적 의미의 ‘압력 기기’에는 압력 용기, 증기 보일러, 열 교환기, 파이프, 압력 부품, 압력 장치가 포함됩니다. 또한 압력과 관련된 부분에 사용되는 모든 부품과 제품 (플랜지, 노즐, 리프팅, 고속 컨넥터 등) 이 압력기기에 포함됩니다.

일반적으로 아래 안전부품을 포함합니다.

• safety valves,

• bursting disc safety devices,

• buckling rods,

• controlled safety pressure relief systems

• pressure switches

• temperature switches

• fluid level switches

PED에 대한 적합성이 확인된 압력기기는 유럽권역에서 유통 판매를 보장받고 나아가 러시아 등 기타의 국가에서도 적합성을 인정합니다.

저장 된 에너지 (압력 볼륨 제품) 및 사용된 유체의 특성에 따라 결정 되는 위험 수준에 따라 제조자 자체 선언을 하는 가장 낮은 수준인 Category I부터 ISO 9001 품질경영 시스템 및/또는 승인기관 (인증 기관 : NB)의 형식시험 (Type Examination)이 요구되는 Category IV까지 분류됩니다.

(3) 대상 제외 기기 Exclusions

이 지침은 부품(components)과 하부 조립품(Sub assemblies)에만 적용 될 뿐이며 산업현장에 설치된 경우 처럼 site에 설치되어 사용자의 책임하에 있는 압력기기에는 적용하지 않습니다. (“assembly of pressure equipment on site and under the responsibility of the user, as in the case of industrial installations”.)

특히 군사용, 운송용 기기 (항공, 해운, 철도, 육상운송 수단에 의해 유체의 운송을 위한 용기: PI Marking 대상)와 기계지침 등 다른 지침에 포함되는 장비는 적용 대상에서 제외합니다.

참조 : 특수한 경우로써 PI Marking과 CE Marking 등 두 가지를 동시에 인증 취득하여야 하는 경우도 있으니 승인기관 (인증 기관 : NB)과 상의 할 것을 권장합니다.

설계, 생산 및 테스트에 관하여 해당되는 많은 표준과 규격이 있으며 이들 규격과 표준 등에는 압력기기의 설계 단계부터 생산 및 시험의 각 단계까지를 포함하여 사용되는 자재 및 재료, 용접 및 테스트 방법과 기준이 제시되어 있습니다.

(4) 압력용기 보호규정 Protection requirements.

압력장비는 내부/외부 압력, 주변 및 운전 온도, 정적 압력과 운전과 시험시의 내용물의 량, 교통, 바람, 지진, 부식 및 침식, 피로에 적절한 강도로 설계 되어야 합니다.

안전한 취급과 운전 그리고 시험, 배출과 배기를 보장하는 수단을 제공하여야 합니다.

허용할 수 있는 압력한계의 초과에 대한 보호조치를 제공해야 합니다.

필요한 경우, 외부화제로 손상한계 요건을 충족시키기 위해 적절한 부품을 설계 및 장착하여야 합니다.

영구 접합의 비파괴 시험은 자격을 갖춘 인원에 의해 수행되어야 합니다. 특히 Category III과 IV의 경우, 인원의 자격에 대해 승인되어야 하며 사용되는 자재와 부품의 추적성을 위한 절차가 수립되어야 합니다.

제조업체는 이 지침의 필수적인 성능 요구 사항을 충족하는 능력을 입증하여야 하고 장비의 취급과 사용에 관한 기술적 설명서를 포함하는 기술문서 (기술 구성 파일 : TCF)를 작성 보관하여야 합니다.

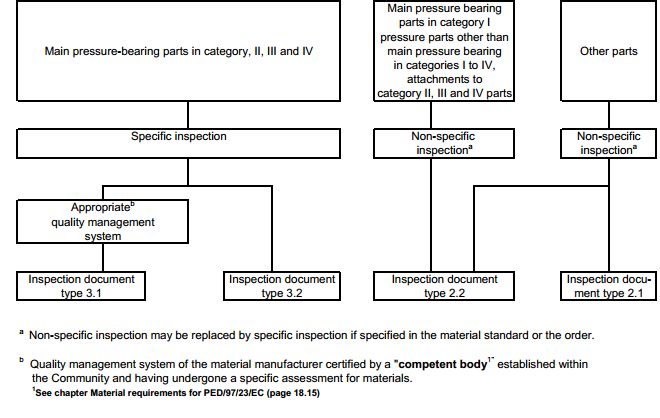

(5) Type of Inspection Documents (IN 10204)

Declaration of compliance with the order “type 2.1″

Document in which the manufacturer declares that the products supplied are in compliance with the requirements of the order, without inclusion of test results.

Test report “type 2.2″

Document in which the manufacturer declares that the products supplied are in compliance with the requirements of the order and in which he supplies test results based on non-specific inspection.

Inspection certificate 3.1 “type 3.1″

Document issued by the manufacturer in which he declares that the products supplied are in compliance with the requirements of the order and in which he supplies test results.

The test unit and the tests to be carried out are defined by the product specification, the official regulation and corresponding rules and/or the order.

The document is validated by the manufacturer’s authorized inspection representative, independent of the manufacturing department.

It shall be permissible for the manufacturer to transfer on to the inspection certificate 3.1 relevant test results obtained by specific inspection on primary or incoming products he uses, provided that the manufacturer operates traceability procedures and can provide the corresponding inspection documents required

Inspection certificate 3.2 “type 3.2″

Document prepared by both the manufacturer’s authorized inspection representative, independent of the manufacturing department and either the purchaser’s authorized inspection representative or the inspector designated by the official regulations and in which they declare that the products supplied are in compliance with

the requirements of the order and in which test results are supplied.

It shall be permissible for the manufacturer to transfer on to the inspection certificate 3.2 relevant test results obtained by specific inspection on primary or incoming products he uses, provided that the manufacturer operates traceability procedures and can provide the corresponding inspection documents required.

Conformity with Annex I section 4.3 of PED 97/23/EC

(6) CE Mark표식

압력 장비는 최소한 다음사항을 표시하여야 합니다.

제조업체명

고유 식별 모델 및 일련 번호

제조년도

최대/최소 허용 압력

CE 로고

(7) 압력용기 지침(PED) 관련 EN규격목록

IN 3-8:2006

Portable fire extinguishers – Part 8: Additional requirements to EN 3-7 for the construction, resistance to pressure and mechanical tests for extinguishers with a maximum allowable pressure equal to or lower than 30 bar

IN 3-8:2006/AC:2007

IN 19:2002

Industrial valves – Marking of metallic valves

IN 267:2009+A1:2011

액체 연료의 자동 강제 통풍 버너

IN 287-1:2011

Qualification test of welders – Fusion welding – Part 1: Steels

IN 334:2005+A1:2009

Gas pressure regulators for inlet pressures up to 100 bar

IN 378-2:2008+A2:2012 (새로운)

냉동 시스템 및 히트 펌프 - 안전 및 환경 요구 사항 - 부품 2: 디자인, 구성, 테스트, 표시 및 문서

IN 593:2009+A1:2011

Industrial valves – Metallic butterfly valves

IN 676:2003+A2:2008

기체 연료를 사용하는 자동 강제 통풍 버너

IN 676:2003+A2:2008/AC:2008

IN 764-5:2002

Pressure Equipment – Part 5: Compliance and Inspection Documentation of Materials

IN 764-7:2002

Pressure equipment – Part 7: Safety systems for unfired pressure equipment

IN 764-7:2002/AC:2006

IN 1057:2006+A1:2010

구리 및 구리 합금 - 원활한, 위생 및 가열 응용 프로그램에서 물과 가스 라운드 구리 관

IN 1092-1:2007

플랜지와 자신의 관절 - 파이프 원형 플랜지, 밸브, 피팅 및 액세서리, PN 지정 - 부품 1: 스틸 플랜지

IN 1092-3:2003

플랜지와 자신의 관절 - 파이프 원형 플랜지, 밸브, 피팅 및 액세서리, PN 지정 - 부품 3: 동합금 플랜지

IN 1092-3:2003/AC:2007

IN 1092-4:2002

플랜지와 자신의 관절 - 파이프 원형 플랜지, 밸브, 피팅 및 액세서리, PN 지정 - 부품 4: 알루미늄 합금 플랜지

IN 1171:2002

Industrial valves – Cast iron gate valves

IN 1252-1:1998

극저온 용기 - 재료 - 부품 1: Toughness requirements for temperatures below -80°C

IN 1252-1:1998/AC:1998

IN 1252-2:2001

극저온 용기 - 재료 - 부품 2: -80 ° C 및 -20 °의 온도에 대한 인성 요구 사항 C

IN 1349:2009

Industrial process control valves

IN 1515-4:2009

Flanges and their joints – Bolting – Part 4: Selection of bolting for equipment subject to the Pressure Equipment Directive 97/23/EC

IN 1562:2012 (새로운)

Founding – Malleable cast irons

IN 1563:2011

Founding – Spheroidal graphite cast irons

IN 1564:2011

Founding – Ausferritic spheroidal graphite cast irons

IN 1591-1:2001+A1:2009

Flanges and their joints – Design rules for gasketed circular flange connections – Part 1: Calculation method

IN 1591-1:2001+A1:2009/AC:2011

IN 1626:2008

Cryogenic vessels – Valves for cryogenic service

IN 1653:1997

Copper and copper alloys – Plate, sheet and circles for boilers, pressure vessels and hot water storage units

IN 1653:1997/A1:2000

IN 1759-3:2003

플랜지와 자신의 관절 - 파이프 원형 플랜지, 밸브, 피팅 및 액세서리, Class designated – Part 3: 동합금 플랜지

IN 1759-3:2003/AC:2004

IN 1759-4:2003

Flanges and their joint – Circular flanges for pipes, 밸브, 피팅 및 액세서리, class designated – Part 4: 알루미늄 합금 플랜지

IN 1797:2001

Cryogenic vessels – Gas/material compatibility

IN 1866:2005

Mobile fire extinguishers

IN 1983:2006

Industrial valves – Steel ball valves

IN 1984:2010

Industrial valves – Steel gate valves

EN ISO 4126-1:2004

Safety devices for protection against excessive pressure – Part 1: Safety valves (ISO 4126-1:2004)

EN ISO 4126-1:2004/AC:2006

EN ISO 4126-3:2006

Safety devices for protection against excessive pressure – Part 3: Safety valves and bursting disc safety devices in combination (ISO 4126-3:2006)

EN ISO 4126-4:2004

Safety devices for protection against excessive pressure – Part 4: Pilot operated safety valves (ISO 4126-4:2004)

EN ISO 4126-5:2004

Safety devices for protection against excessive pressure – Part 5: Controlled safety pressure relief systems (CSPRS) (ISO 4126-5:2004)

EN ISO 4126-5:2004/AC:2008

EN ISO 9606-2:2004

Qualification test of welders – Fusion welding – Part 2: Aluminium and aluminium alloys (ISO 9606-2:2004)

EN ISO 9606-3:1999

Approval testing of welders – Fusion welding – Part 3: Copper and copper alloys (ISO 9606-3:1999)

EN ISO 9606-4:1999

Approval testing of welders – Fusion welding – Part 4: Nickel and nickel alloys (ISO 9606-4:1999)

EN ISO 9606-5:2000

Approval testing of welders – Fusion welding – Part 5: Titanium and titanium alloys, zirconium and zirconium alloys (ISO 9606-5:2000)

EN ISO 9712:2012 (새로운)

Non-destructive testing – Qualification and certification of NDT personnel (ISO 9712:2012)

IN 10028-1:2007+A1:2009

Flat products made of steels for pressure purposes – Part 1: 일반 요구 사항

IN 10028-1:2007+A1:2009/AC:2009

IN 10028-2:2009

Flat products made of steels for pressure purposes – Part 2: Non-alloy and alloy steels with specified elevated temperature properties

IN 10028-3:2009

Flat products made of steels for pressure purposes – Part 3: Weldable fine grain steels, normalized

IN 10028-4:2009

Flat products made of steels for pressure purposes – Part 4: Nickel alloy steels with specified low temperature properties

IN 10028-5:2009

Flat products made of steels for pressure purposes – Part 5: Weldable fine grain steels, thermomechanically rolled

IN 10028-6:2009

Flat products made of steels for pressure purposes – Part 6: Weldable fine grain steels, quenched and tempered

IN 10028-7:2007

Flat products made of steels for pressure purposes – Part 7: 스테인리스 강

IN 10204:2004

Metallic products – Types of inspection documents

IN 10213:2007

Steel castings for pressure purposes

IN 10213:2007/AC:2008

IN 10216-1:2002

Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 1: Non-alloy steel tubes with specified room temperature properties

IN 10216-1:2002/A1:2004

IN 10216-2:2002+A2:2007

Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties

IN 10216-3:2002

Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 3: Alloy fine grain steel tubes

IN 10216-3:2002/A1:2004

IN 10216-4:2002

Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 4: Non-alloy and alloy steel tubes with specified low temperature properties

IN 10216-4:2002/A1:2004

IN 10216-5:2004

Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 5: Stainless steel tubes

IN 10216-5:2004/AC:2008

IN 10217-1:2002

Welded steel tubes for pressure purposes – Technical delivery conditions – Part 1: Non-alloy steel tubes with specified room temperature properties

IN 10217-1:2002/A1:2005

IN 10217-2:2002

Welded steel tubes for pressure purposes – Technical delivery conditions – Part 2: Electric welded non-alloy and alloy steel tubes with specified elevated temperature properties

IN 10217-2:2002/A1:2005

IN 10217-3:2002

Welded steel tubes for pressure purposes – Technical delivery conditions – Part 3: Alloy fine grain steel tubes

IN 10217-3:2002/A1:2005

IN 10217-4:2002

Welded steel tubes for pressure purposes – Technical delivery conditions – Part 4: Electric welded non-alloy steel tubes with specified low temperature properties

IN 10217-4:2002/A1:2005

IN 10217-5:2002

Welded steel tubes for pressure purposes – Technical delivery conditions – Part 5: Submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties

IN 10217-5:2002/A1:2005

IN 10217-6:2002

Welded steel tubes for pressure purposes – Technical delivery conditions – Part 6: Submerged arc welded non-alloy steel tubes with specified low temperature properties

IN 10217-6:2002/A1:2005

IN 10217-7:2005

Welded steel tubes for pressure purposes – Technical delivery conditions – Part 7: Stainless steel tubes

IN 10222-1:1998

압력을 위해 단강 - 부품 1: 열린 다이 단조에 대한 일반 요구 사항

IN 10222-1:1998/A1:2002

IN 10222-2:1999

압력을 위해 단강 - 부품 2: Ferritic and martensitic steels with specified elevated temperature properties

IN 10222-2:1999/AC:2000

IN 10222-3:1998

압력을 위해 단강 - 부품 3: Nickel steels with specified low temperature properties

IN 10222-4:1998

압력을 위해 단강 - 부품 4: Weldable fine grain steels with high proof strength

IN 10222-4:1998/A1:2001

IN 10222-5:1999

압력을 위해 단강 - 부품 5: Martensitic, austenitic and austenitic-ferritic stainless steels

IN 10222-5:1999/AC:2000

IN 10253-2:2007

Butt-welding pipe fittings – Part 2: Non alloy and ferritic alloy steels with specific inspection requirements

IN 10253-4:2008

Butt-welding pipe fittings – Part 4: Wrought austenitic and austenitic-ferritic (duplex) stainless steels with specific inspection requirements

IN 10253-4:2008/AC:2009

IN 10269:1999

Steels and nickel alloys for fasteners with specified elevated and/or low temperature properties

IN 10269:1999/A1:2006

IN 10269:1999/A1:2006/AC:2008

IN 10272:2007

Stainless steel bars for pressure purposes

IN 10273:2007

Hot rolled weldable steel bars for pressure purposes with specified elevated temperature properties

IN 10305-4:2011

Steel tubes for precision applications – Technical delivery conditions – Part 4: Seamless cold drawn tubes for hydraulic and pneumatic power systems

IN 10305-6:2005

Steel tubes for precision applications – Technical delivery conditions – Part 6: Welded cold drawn tubes for hydraulic and pneumatic power systems

EN ISO 10931:2005

Plastics piping systems for industrial applications – Poly(vinylidene fluoride) (PVDF) – Specifications for components and the system (ISO 10931:2005)

IN 12178:2003

Refrigerating systems and heat pumps – Liquid level indicating devices – Requirements, testing and marking

IN 12263:1998

Refrigerating systems and heat pumps – Safety switching devices for limiting the pressure – Requirements and tests

IN 12266-1:2012 (새로운)

산업용 밸브 - 금속 밸브의 검사 - 부품 1: 압력 테스트, 시험 방법 및 판정 기준 - 필수 요구 사항

IN 12284:2003

Refrigerating systems and heat pumps – Valves – Requirements, testing and marking

IN 12288:2010

산업용 밸브 - 구리 합금 게이트 밸브

IN 12334:2001

산업용 밸브 - 주철 체크 밸브

IN 12334:2001/A1:2004

IN 12334:2001/AC:2002

IN 12392:2000

알루미늄 및 알루미늄 합금 - 단조 제품 - 압력 기기의 생산을위한 제품에 대한 특별 요구 사항

IN 12420:1999

구리 및 구리 합금 - 단조

IN 12434:2000

Cryogenic vessels – Cryogenic flexible hoses

IN 12434:2000/AC:2001

IN 12451:2012 (새로운)

구리 및 구리 합금 - 원활한, 열교환 라운드 튜브

IN 12452:2012 (새로운)

구리 및 구리 합금 - 압연, 지느러미를 가진, 열교환 원활한 튜브

IN 12516-1:2005

산업용 밸브 - 쉘 디자인의 힘 - 부품 1: 스틸 밸브 쉘의 집계 방법

IN 12516-1:2005/AC:2007

IN 12516-2:2004

산업용 밸브 - 쉘 디자인의 힘 - 부품 2: 스틸 밸브 쉘의 계산 방법

IN 12516-3:2002

밸브 - 쉘 디자인의 힘 - 부품 3: 실험 방법

IN 12516-3:2002/AC:2003

IN 12516-4:2008

산업용 밸브 - 쉘 디자인의 힘 - 부품 4: 강철보다 다른 금속 재료의 제조 밸브 쉘의 계산 방법

IN 12542:2010

LPG equipment and accessories – Static welded steel cylindrical tanks, serially produced for the storage of Liquefied Petroleum Gas (LPG) having a volume not greater than 13 m³ – Design and manufacture

IN 12735-1:2010

구리 및 구리 합금 - 원활한, 에어컨과 냉장 라운드 구리 튜브 - 부품 1: 배관 시스템에 대한 관

IN 12735-2:2010

구리 및 구리 합금 - 원활한, 에어컨과 냉장 라운드 구리 튜브 - 부품 2: 장비 관

IN 12778:2002

Cookware – Pressure cookers for domestic use

IN 12778:2002/A1:2005

IN 12778:2002/AC:2003

IN 12952-1:2001

물 관 보일러 및 보조 설비 - 부품 1: General

IN 12952-2:2011

물 관 보일러 및 보조 설비 - 부품 2: Materials for pressure parts of boilers and accessories

IN 12952-3:2011

물 관 보일러 및 보조 설비 - 부품 3: Design and calculation for pressure parts of the boiler

IN 12952-5:2011

물 관 보일러 및 보조 설비 - 부품 5: Workmanship and construction of pressure parts of the boiler

IN 12952-6:2011

물 관 보일러 및 보조 설비 - 부품 6: Inspection during construction; documentation and marking of pressure parts of the boiler

IN 12952-7:2002

물 관 보일러 및 보조 설비 - 부품 7: 보일러 장비에 대한 요구 사항

IN 12952-8:2002

물 관 보일러 및 보조 설비 - 부품 8: 보일러 액체 및 가스 연료 시스템을 발사하기위한 요구 사항

IN 12952-9:2002

물 관 보일러 및 보조 설비 - 부품 9: 보일러 분쇄 고체 연료를 사용하는 시스템을 발사하기위한 요구 사항

IN 12952-10:2002

물 관 보일러 및 보조 설비 - 부품 10: 과도한 압력에 대한 안전에 대한 요구 사항

IN 12952-11:2007

물 관 보일러 및 보조 설비 - 부품 11: Requirements for limiting devices of the boiler and accessories

IN 12952-14:2004

물 관 보일러 및 보조 설비 - 부품 14: Requirements for flue gas DENOX-systems using liquefied pressurized ammonia and ammonia water solution

IN 12952-16:2002

물 관 보일러 및 보조 설비 - 부품 16: 보일러 고체 연료를 사용하는 시스템을 발사 쇠 격자 및 유동에 대한 요구 사항

IN 12953-1:2012 (새로운)

쉘 보일러 - 부품 1: General

IN 12953-2:2012 (새로운)

쉘 보일러 - 부품 2: Materials for pressure parts of boilers and accessories

IN 12953-3:2002

쉘 보일러 - 부품 3: Design and calculation for pressure parts

IN 12953-4:2002

쉘 보일러 - 부품 4: Workmanship and construction of pressure parts of the boiler

IN 12953-5:2002

쉘 보일러 - 부품 5: Inspection during construction, documentation and marking of pressure parts of the boiler

IN 12953-6:2011

Shell Boilers – Part 6: 보일러 장비에 대한 요구 사항

IN 12953-7:2002

쉘 보일러 - 부품 7 : 보일러 액체 및 가스 연료 시스템을 발사하기위한 요구 사항

IN 12953-8:2001

쉘 보일러 - 부품 8: 과도한 압력에 대한 안전에 대한 요구 사항

IN 12953-8:2001/AC:2002

IN 12953-9:2007

쉘 보일러 - 부품 9: Requirements for limiting devices of the boiler and accessories

IN 12953-12:2003

쉘 보일러 - 부품 12: Requirements for grate firing systems for solid fuels for the boiler

IN 12953-13:2012 (새로운)

쉘 보일러 - 부품 13: 사용 설명서

IN 13121-1:2003

GRP tanks and vessels for use above ground – Part 1: Raw materials – Specification conditions and acceptance conditions

IN 13121-2:2003

GRP tanks and vessels for use above ground – Part 2: Composite materials – Chemical resistance

IN 13121-3:2008+A1:2010

GRP tanks and vessels for use above ground – Part 3: Design and workmanship

IN 13121-3:2008+A1:2010/AC:2011

IN 13134:2000

브레이징 - 승인 절차

IN 13136:2001

Refrigerating systems and heat pumps – Pressure relief devices and their associated piping – Methods for calculation

IN 13136:2001/A1:2005

IN 13175:2003+A2:2007

LPG equipment and accessories – Specification and testing for Liquefied Petroleum Gas (LPG) tank valves and fittings

IN 13348:2008

구리 및 구리 합금 - 원활한, 의료 가스 또는 진공 라운드 구리 관

IN 13371:2001

Cryogenic vessels – Couplings for cryogenic service

IN 13397:2001

Industrial valves – Diaphragm valves made of metallic materials

IN 13445-1:2009

Unfired pressure vessels – Part 1: General

IN 13445-2:2009

Unfired pressure vessels – Part 2: Materials

IN 13445-2:2009/A1:2012 (새로운)

IN 13445-2:2009/A2:2012 (새로운)

IN 13445-3:2009

Unfired pressure vessels – Part 3: 디자인

IN 13445-3:2009/A1:2012 (새로운)

IN 13445-4:2009

Unfired pressure vessels – Part 4: Fabrication

IN 13445-4:2009/A1:2011

IN 13445-5:2009

Unfired pressure vessels – Part 5: Inspection and testing

IN 13445-5:2009/A2:2011

IN 13445-5:2009/A3:2011

IN 13445-5:2009/A1:2011

IN 13445-6:2009

Unfired pressure vessels – Part 6: Requirements for the design and fabrication of pressure vessels and pressure parts constructed from spheroidal graphite cast iron

IN 13445-8:2009

Unfired pressure vessels – Part 8: Additional requirements for pressure vessels of aluminium and aluminium alloys

IN 13458-1:2002

Cryogenic vessels – Static vacuum insulated vessels – Part 1: Fundamental requirements

IN 13458-2:2002

Cryogenic vessels – Static vacuum insulated vessels – Part 2: 디자인, fabrication, inspection and testing

IN 13458-2:2002/AC:2006

IN 13458-3:2003

Cryogenic vessels – Static vacuum insulated vessels – Part 3: Operational requirements

IN 13458-3:2003/A1:2005

IN 13480-1:2012 (새로운)

Metallic industrial piping – Part 1: General

IN 13480-2:2012 (새로운)

Metallic industrial piping – Part 2: Materials

IN 13480-3:2012 (새로운)

Metallic industrial piping – Part 3: Design and calculation

IN 13480-4:2012 (새로운)

Metallic industrial piping – Part 4: Fabrication and installation

IN 13480-5:2012 (새로운)

Metallic industrial piping – Part 5: Inspection and testing

IN 13480-6:2012 (새로운)

Metallic industrial piping – Part 6: Additional requirements for buried piping

IN 13480-8:2012 (새로운)

Metallic industrial piping – Part 8: Additional requirements for aluminium and aluminium alloy piping

EN ISO 13585:2012 (새로운)

Brazing – Qualification test of brazers and brazing operators (ISO 13585:2012)

IN 13611:2007+A2:2011

Safety and control devices for gas burners and gas burning appliances – General requirements

IN 13648-1:2008

Cryogenic vessels – Safety devices for protection against excessive pressure – Part 1: Safety valves for cryogenic service

IN 13648-2:2002

Cryogenic vessels – Safety devices for protection against excessive pressure – Part 2: Bursting disc safety devices for cryogenic service

IN 13648-3:2002

Cryogenic vessels – Safety devices for protection against excessive pressure – Part 3: Determination of required discharge – Capacity and sizing

IN 13709:2010

Industrial valves – Steel globe and globe stop and check valves

IN 13789:2010

Industrial valves – Cast iron globe valves

IN 13831:2007

Closed expansion vessels with built in diaphragm for installation in water

IN 13835:2012 (새로운)

Founding – Austenitic cast irons

IN 13923:2005

Filament-wound FRP pressure vessels – Materials, design, manufacturing and testing

IN 14071:2004

Pressure relief valves for LPG tanks – Ancillary equipment

IN 14129:2004

Pressure relief valves for LPG tanks

IN 14197-1:2003

Cryogenic vessels – Static non-vacuum insulated vessels – Part 1: Fundamental requirements

IN 14197-2:2003

Cryogenic vessels – Static non-vacuum insulated vessels – Part 2: 디자인, fabrication, inspection and testing

IN 14197-2:2003/A1:2006

IN 14197-2:2003/AC:2006

IN 14197-3:2004

Cryogenic vessels – Static non-vacuum insulated vessels – Part 3: Operational requirements

IN 14197-3:2004/A1:2005

IN 14197-3:2004/AC:2004

IN 14222:2003

Stainless steel shell boilers

IN 14276-1:2006+A1:2011

Pressure equipment for refrigerating systems and heat pumps – Part 1: Vessels – General requirements

IN 14276-2:2007+A1:2011

Pressure equipment for refrigerating systems and heat pumps – Part 2: Piping – General requirements

IN 14341:2006

Industrial valves – Steel check valves

IN 14359:2006+A1:2010

Gas-loaded accumulators for fluid power applications

IN 14382:2005+A1:2009

Safety devices for gas pressure regulating stations and installations – Gas safety shut-off devices for inlet pressures up to 100 bar

IN 14382:2005+A1:2009/AC:2009

IN 14394:2005+A1:2008

Heating boilers – Heating boilers with forced draught burners – Nominal heat output not exceeding 10 MW and maximum operating temperature of 110 ° C

IN 14570:2005

Equipping of LPG tanks, overground and underground

IN 14570:2005/A1:2006

IN 14585-1:2006

Corrugated metal hose assemblies for pressure applications – Part 1: 요구 사항

IN 14917:2009+A1:2012 (새로운)

Metal bellows expansion joints for pressure applications

IN 15001-1:2009

Gas Infrastructure – Gas installation pipework with an operating pressure greater than 0,5 bar for industrial installations and greater than 5 bar for industrial and non-industrial installations – Part 1: Detailed functional requirements for design, materials, 구성, inspection and testing

EN ISO 15493:2003

Plastics piping systems for industrial applications – Acrylonitrile-butadiene-styrene (ABS), unplasticized poly(비닐 클로라이드) (PVC-U) and chlorinated poly(비닐 클로라이드) (PVC-C) – Specifications for components and the system – Metric series (ISO 15493:2003)

EN ISO 15494:2003

Plastics piping systems for industrial applications – Polybutene (PB), polyethylene (PE) and polypropylene (PP) – Specifications for components and the system – Metric series (ISO 15494:2003)

EN ISO 15613:2004

Specification and qualification of welding procedures for metallic materials – Qualification based on pre-production welding test (ISO 15613:2004)

EN ISO 15614-1:2004

Specification and qualification of welding procedures for metallic materials – Welding procedure test – Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys (ISO 15614-1:2004)

EN ISO 15614-1:2004/A1:2008

EN ISO 15614-1:2004/A2:2012 (새로운)

EN ISO 15614-2:2005

Specification and qualification of welding procedures for metallic materials – Welding procedure test – Part 2: Arc welding of aluminium and its alloys (ISO 15614-2:2005)

EN ISO 15614-2:2005/AC:2009

EN ISO 15614-4:2005

Specification and qualification of welding procedures for metallic materials – Welding procedure test – Part 4: Finishing welding of aluminium castings (ISO 15614-4:2005)

EN ISO 15614-4:2005/AC:2007

EN ISO 15614-5:2004

Specification and qualification of welding procedures for metallic materials – Welding procedure test – Part 5: Arc welding of titanium, zirconium and their alloys (ISO 15614-5:2004)

EN ISO 15614-6:2006

Specification and qualification of welding procedures for metallic materials – Welding procedure test – Part 6: Arc and gas welding of copper and its alloys (ISO 15614-6:2006)

EN ISO 15614-7:2007

Specification and qualification of welding procedures for metallic materials – Welding procedure test – Part 7: Overlay welding (ISO 15614-7:2007)

EN ISO 15614-8:2002

Specification and qualification of welding procedures for metallic materials – Welding procedure test – Part 8: Welding of tubes to tube-plate joints (ISO 15614-8:2002)

EN ISO 15614-11:2002

Specification and qualification of welding procedures for metallic materials – Welding procedure test – Part 11: Electron and laser beam welding (ISO 15614-11:2002)

EN ISO 15620:2000

Welding – Friction welding of metallic materials (ISO 15620:2000)

IN 15776:2011

Unfired pressure vessels – Requirements for the design and fabrication of pressure vessels and pressure parts constructed from cast iron with an elongation after fracture equal or less than 15 %

EN ISO 16135:2006

Industrial valves – Ball valves of thermoplastics materials (ISO 16135:2006)

EN ISO 16136:2006

Industrial valves – Butterfly valves of thermoplastics materials (ISO 16136:2006)

EN ISO 16137:2006

Industrial valves – Check valves of thermoplastics materials (ISO 16137:2006)

EN ISO 16138:2006

Industrial valves – Diaphragm valves of thermoplastics materials (ISO 16138:2006)

EN ISO 16139:2006

Industrial valves – Gate valves of thermoplastics materials (ISO 16139:2006)

EN ISO 21787:2006

Industrial valves – Globe valves of thermoplastics materials (ISO 21787:2006)